- Food & Beverage/Pharmaceutical

- Energy Saving System

- Wastewater Treatment System

- Water & Environment Plant

- Overview

- Anaerobic Wastewater Treatment System

- Aerobic Wastewater Treatment System

- Nitrogen Wastewater Treatment System

- Gas Refining System

- Dehydration System

- Project Achievement

IC(Internal Circulation) REACTOR

Minimize required land

|

Low operation cost

|

High amount of microorganisms

|

Hermetically Sealed Structure

|

Biogas generated

|

Verified performance

|

Classification of biological wastewater treatment

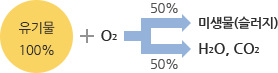

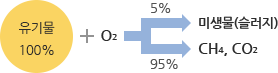

Biological wastewater treatment can be classified into aerobic and anaerobic according to the types of microorganisms used. The resolvents in wastewater are decomposed as below.

· Wastewater treatment by aerobic microorganisms

· Wastewater treatment by anaerobic microorganisms

BIOPAQ ICX(ICXperience)

This is the latest technology developed based on the experience in IC Reactor, which can be restructured into ICX from anaerobic digesting tank with the potential issue of loss of microorganisms.

Features

- · Lower initial investment cost by remodeling unused tanks (civil engineering, steel frames, etc.) into reactors

- · Can be designed into compact structure with high space loading (30~40kgCODcr/m3/day)

- · Capable of treating wastewater of wider range due to good mixing property

- · Use anaerobic microorganisms in granules

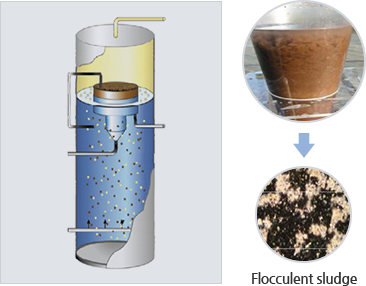

AFR(Anaerobic Floatation Reactor)

This facility treats wastewater containing F.O.G. (Fat, Oil, Grease), protein and starch and produces biogas.

Features

- · Does not require pressurized floatation tank and deoiler tank in pretreatment facility

- · Takes 1-8 days of residence time

- · Capable of producing high volume of biogas

- · Use flocculent anaerobic microorganisms

- · Applied to dairy product processing, ice cream, manufacturing cooking oil, slaughterhouse and food waste effluent